CNC Kutembenuza mitundu chitsulo chosapanga dzimbiri / aluminiyamu yolumikizana yosinthika yamagalimoto

Zokhotakhota nsagwada Couplings

Ma Curved Jaw couplings amatha kugwiritsidwa ntchito pazinthu zambiri ndikukhala ngati cholumikizira zolinga zonse.Mapangidwe oyambira a Curved Jaw amalola kuti pakhale torque yapamwamba kwambiri pamapangidwe apakatikati.Dzino lopindika limakhala ndi malo olumikizana kwambiri omwe amapatsa mphamvu ya torque yayikulu, komanso amachepetsa kuthamanga kwa m'mphepete.Idzagwirizana ndi misalignments ya axial, radial ndi angular shaft.

Malowa amapangidwa kuchokera kuzinthu zosiyanasiyana monga: aluminiyamu, imvi, chitsulo, chitsulo, chitsulo chosapanga dzimbiri, ndi chitsulo chosapanga dzimbiri.Zinthu za akangaude zimapezeka mumitundu yosiyanasiyana ya durometer ku Urethane & Hytrel.Akangaude amatha kugwira ntchito mozungulira nthawi yogwira ntchito zolemetsa zomwe zimaphatikizira kutsitsa ndikuchepetsa kugwedezeka kwamagetsi mudongosolo.

| Chitsanzo | Kukula kwake (mm) | Chiwerengero chaTorque (Nm) | MaxTorque (Nm) | Liwiro lalikulu | Diameter Yakunja (mm) | Utali (mm) | Bore Tolerance (mm) |

| HS -TCN-14C | 3 ~ 7 | 0.7 | 1.4 | 45000 | 14 | 22 | + 0.6-0 |

| HS-TCN-20C-R | 4-11 | 1.8 | 3.6 | 31000 | 20 | 30 | + 0.8-0 |

| Zithunzi za HS-TCN-30C-R | 6-16 | 4 | 8 | 21000 | 30 | 35 | + 1.0 ~ 0 |

| HS-TCN-40C-R | 8-28 | 4.9 | 9.8 | 15000 | 40 | 66 | + 1.2 ~ 0 |

| Chithunzi cha HS-TCN-55C-R | 9.5-32 | 17 | 34 | 11000 | 55 | 78 | + 1.4 ~ 0 |

| Mtengo wa HS-TCN-65C-R | 12.7-38.1 | 46 | 92 | 9000 | 65 | 90 | + 1.5 ~ 0 |

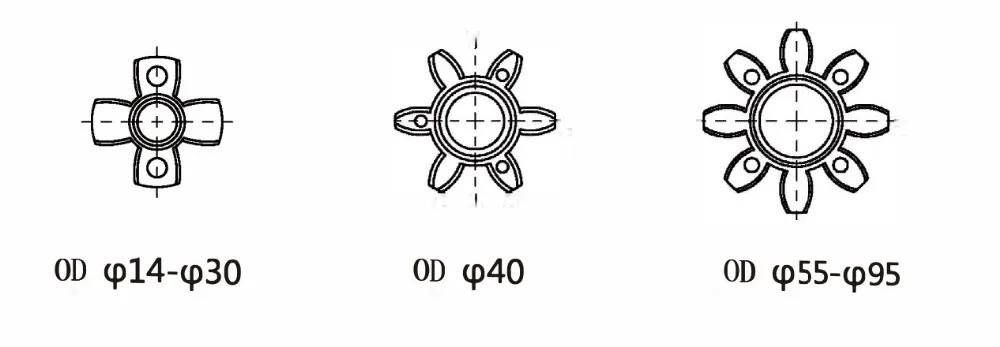

Kangaude Makhalidwe

Kulumikizana kwa nsagwada kumaphatikizapo zitsulo ziwiri zachitsulo ndi "spider" elastomeric.akangaude akupezeka mu

mitundu yosiyanasiyana ya kuuma durometers, iliyonse imadziwika mosavuta ndi mtundu wake.

| Kuuma | Mtundu | Zakuthupi | Kutentha Kusiyanasiyana | Mapulogalamu |

| 80 Shore A | Buluu | Polyurethane | -50 ~+80 .C | Wabwino damping |

| 92 Nyanja A | Yellow | Polyurethane | -40~+90 .C | Kunyowetsa pang'ono, ntchito wamba |

| 98 Shore A | Chofiira | Polyurethane | -30 ~+90 .C | Kugwiritsa ntchito torque yayikulu |

| 64 Mtsinje D | Green | Polyurethane | -50 ~+120 .C | Torque yapamwamba, kutentha kwambiri |

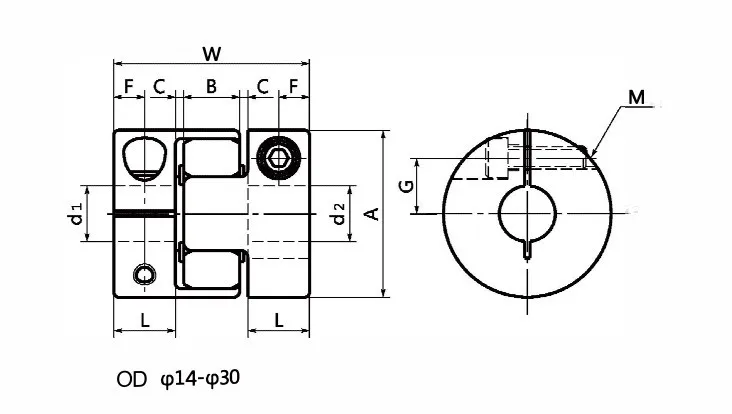

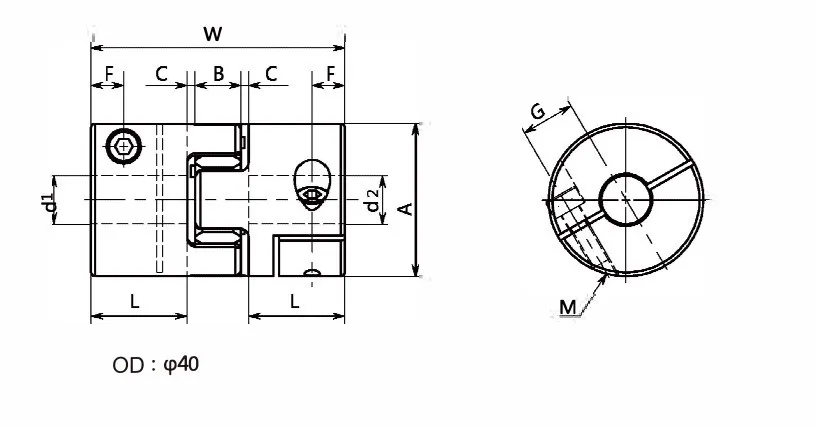

Coupling muyeso chidziwitso

| A | L | W | B | C | F | G | M |

| 14 | 7 | 22 | 6 | 1 | 3.5 | 4/5 | M2/M1.6 |

| 20 | 10 | 30 | 8 | 1 | 5 | 6.5/7.5 | M2.5/M2 |

| 30 | 11 | 35 | 10 | 1.5 | 8.5 | 10/11 | M4/M3 |

| A | L | W | B | C | F | G | M |

| 40 | 25 | 66 | 12 | 2 | 8.5 | 14/15.75 | M5/M4 |

| A | L | W | B | C | F | G | M |

| 55 | 30 | 78 | 14 | 2 | 10.5 | 20/21 | M6/M5 |

| 60 | 35 | 90 | 15 | 2.5 | 13 | 24/25 | M8/M6 |